elcom

Pallet transfer system ITS 24V

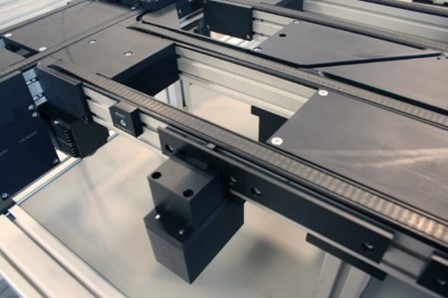

The ITS 24V Modular Transfer maintains the movement characteristics of the workpiece pallets provided by two parallel belts, facilitating the installation of stops, indexing and direction change accessories. However, it also incorporates additional features.

Utility of the ITS 24V Modular Transfer

This transfer is equipped with two parallel belts for the movement of workpiece pallets, facilitating the installation of stops, indexing and direction change accessories. It moves and accumulates 100×100, 150×150, 200×200, 300×300 and 400×400 pallets for non-continuous flows, thus enabling automatic or individual workstations to be managed.

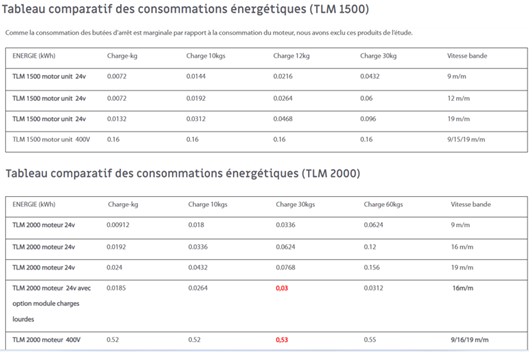

Example of energy consumption

In order to understand the table :

For a TLM 2000 unit with a single 400v motor, loaded with 30 kg, the transfer will consume 0.53kWh.

For a TLM 2000 unit with a 24v motor equipped with a heavy load module, loaded with 30 kg, the transfer will only consume 0.03kWh.

The savings ratio is almost 18 !

For example, imagine that you have a transfer system comprising five lines equipped with ten 380V motors. These motors are responsible for transporting loads of 30 kg each. The system operates for 7728 hours, spread over three eight-hour shifts, over a period of 48 weeks. Using this configuration, your electricity consumption would be 50 × 0.53 × 7728 = 204,792 kWh.

Assuming an average electricity price of €0.17/kWh, the total cost would be €34,814 per year. However, if you opt for 24V TLM solutions, with an operating factor of 0.8, for the same configuration, the annual cost would be reduced to 50 × 0.03 × 6182 × 0.17 = €1576.

In comparison, this represents a saving of more than €30,000 on your electricity bill!

If you would like more details on the possibilities for optimizing your conveyors and transfer lines, we invite you to contact one of our experts. A brief, no-obligation discussion of 30 minutes will be enough to understand your challenges and identify the potential for reducing electricity consumption on your production sites.

The advantages of modular transfer

The ITS 24V Modular Transfer stands out for its reduced energy consumption, thus contributing to the preservation of the environment. Additionally, it offers benefits in terms of installation time, reduced commissioning costs and integration. Its “plug and play” concept allows for quick and easy installation, with the removal of solenoids, pneumatic connectors and hoses, simplifying operations.

The ITS 24V Modular Transfer offers a significant reduction in noise compared to pneumatic systems, which improves working conditions. In addition, since no pneumatic network is required, it is non-polluting.

Thanks to 24V ITS transfers, you will benefit from numerous advantages:

- Low energy consumption: 50% to 90% reduction in consumption depending on the load

- Electronic adjustment of motor parameters (acceleration, speed, deceleration)

- Reduction or removal of the tire

- Possibility of automatically controlling speeds during operation by program, depending on the load

- Frequent stopping and restarting of motors allowed thanks to the epicyclic gearbox (reduction in consumption)

- Possibility of stopping conveyor belts in the event of prolonged stoppage or saturation of one or more sections

- Reduction of clutter

- Plug & Play concept (cards and programs integrated into the engine)

Another advantage of this system is its greater interchangeability, which facilitates subsequent modifications and adaptations. It can also be controlled via a network (bus system), providing connectivity and centralized management.

TLM 2000-ITS 24V are designed for use in a normal industrial environment, such as an assembly workshop or equivalent, in a dry environment.

The maximum load applicable to the transfer system is given in the catalogue and must always be respected.

To ensure that the transfer system operates correctly for optimum service life, follow these guidelines:

× Operating temperature between 0 and 40°C,

× Avoid dusty or smoky atmospheres,

× Avoid accumulation of sharp-edged objects on the conveyor,

× Avoid positioning the machine in direct sunlight.

TLM 2000-ITS 24V linear transfer units are designed to move and position pallets of workpieces in the configuration required by the end customer. They are designed to be incorporated into the customer’s complete line.

video of transfer ITS 24V

characteristics

The ITS 24V Modular Transfer is typical for energy saving due to several features that contribute to reduced energy consumption:

- Increased precision: The ITS 24V Modular Transfer is also known for its high precision, with a tolerance of (+/-) 0.03 mm. This precision helps optimize assembly processes, reducing errors and necessary adjustments. By avoiding unnecessary movements or constant corrections, the system saves energy by avoiding losses related to excessive movements or subsequent repairs.

- Network control (bus system): The ITS 24V Modular Transfer offers the possibility of being controlled by a network, which allows centralized management and optimization of operations. Thanks to this precise control, it is possible to regulate and minimize energy consumption by adapting movements, stops and operations to the specific needs of each workstation.

Overall, the ITS 24V Modular Transfer stands out for its energy-saving design. By using low voltage, providing high precision and enabling precise network control, it achieves lower power consumption while maintaining optimal performance. This makes it an attractive choice for industries looking to improve their energy efficiency.

It should be noted that the ITS 24V Modular Transfer can be adapted and configured according to the specific needs of each industry and application. Its use may vary depending on power requirements, safety standards and the characteristics of each industrial sector.

The components of a transfer

For transfers, there are different parts involved in the system which ensure its proper functioning and understand what the elements that compose it are used for.

Each part of the transfer system fulfills a specific role to ensure efficient and accurate transfer of pallets, providing features such as stopping, positioning, diversion and route flexibility.

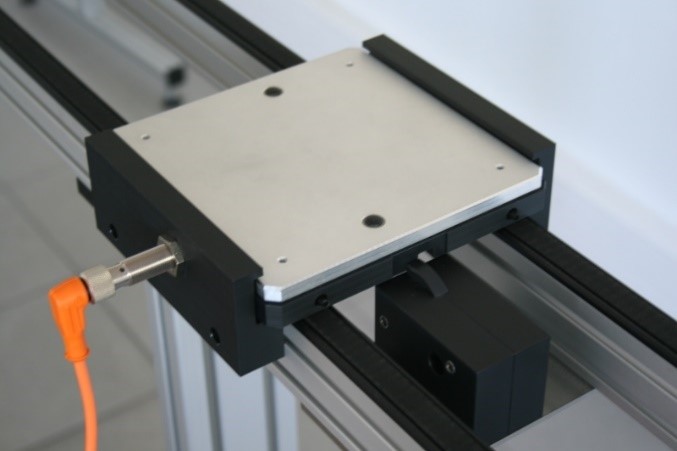

CONVEYING UNIT 24 V TIMING BELT

Moving and accumulating of workpiece carriers 150×150.

Conveying unit 24 V timing belt elcom ITS

The conveying unit 24 V is supplied with a

factory-programmed brushless motor according

to your speed and acceleration ramp requirements.

Speed : 9 to 19 m/min.

STOPPER 24 V

Stopping workpiece carriers during process requiring no accuracy.

Stopping the workpiece carriers in order to respect conveying priorities at the end of the derivation

Simple effect stopper controlled by servomotor.

POSITIONING UNIT FOR STATION 24 V AUTOMATIC STOPPER

Stopping and positioning workpiece pallets for operations requiring accuracy.

Positioning unit for station 24 V automatic stopper elcom ITS

Locating of positioning unit platform by brushless gear motor

and encoder combined with an irreversible screw-and-nut system.

The stopper rectracting is provided by that same movement.

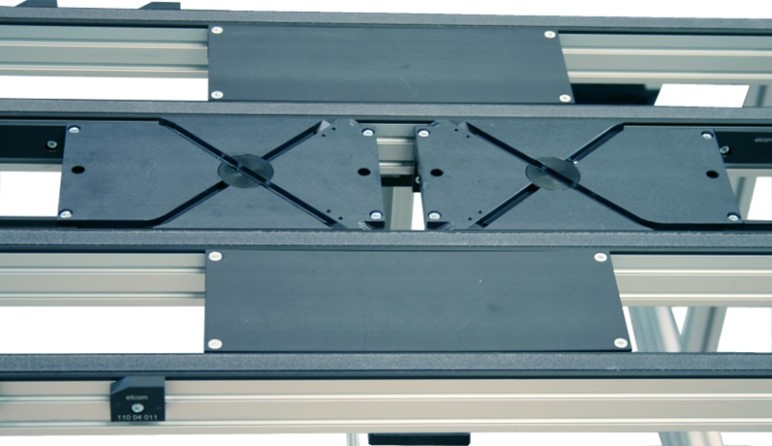

DOUBLE CAM 24 V

Allow deviation of workpiece carriers from a main line to a secondary line without additional motorization.

Two brushless gear motors controlled by a control box ensure the rotation of the selector.

This feature allows pallets to be directed to another line or process without disrupting the main transfer flow, providing great flexibility and optimization of transfer routes.

Derivation 24 V

Derivations have to be used with a cam. They allow potential divertion or not of the workpiece carrier

Two brushless gear motors controlled by a control box ensure the movement.

One question ?

Our experts are here to answer your questions, support you, and guide you through all your projects.