Experts in aluminium profiles, industrial conveyors and workpiece pallet transfer since 35 years

Experts in

since 35 years

Let’s work together to find a solution to your industrial process problems.

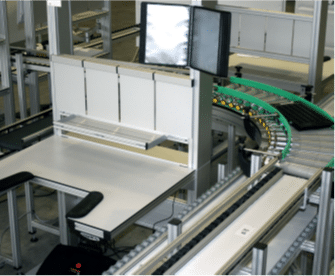

Industrial conveyors

Discover our different technologies : belt conveyors, roller conveyors...

Workpiece pallet transfer

Discover our different technologies depending on the size on your products, the work load, the environment, the production rate !

A large portfolio

0

years

Designer of modular solutions for more than 35 years

0

p.

at the heart of our strategy

0

M€

of revenue

ISO 9001 :2015

ISO 14001

They trust us

Stäubli

Michelin

Schneider Electric

Groupe SEB

Gallery

- All

- Aluminum profiles

- Conveyors

- Transfer system

One question?

Our experts are here to answer your questions, support you, and guide you through all your projects.